IBM Maximo Application Suite

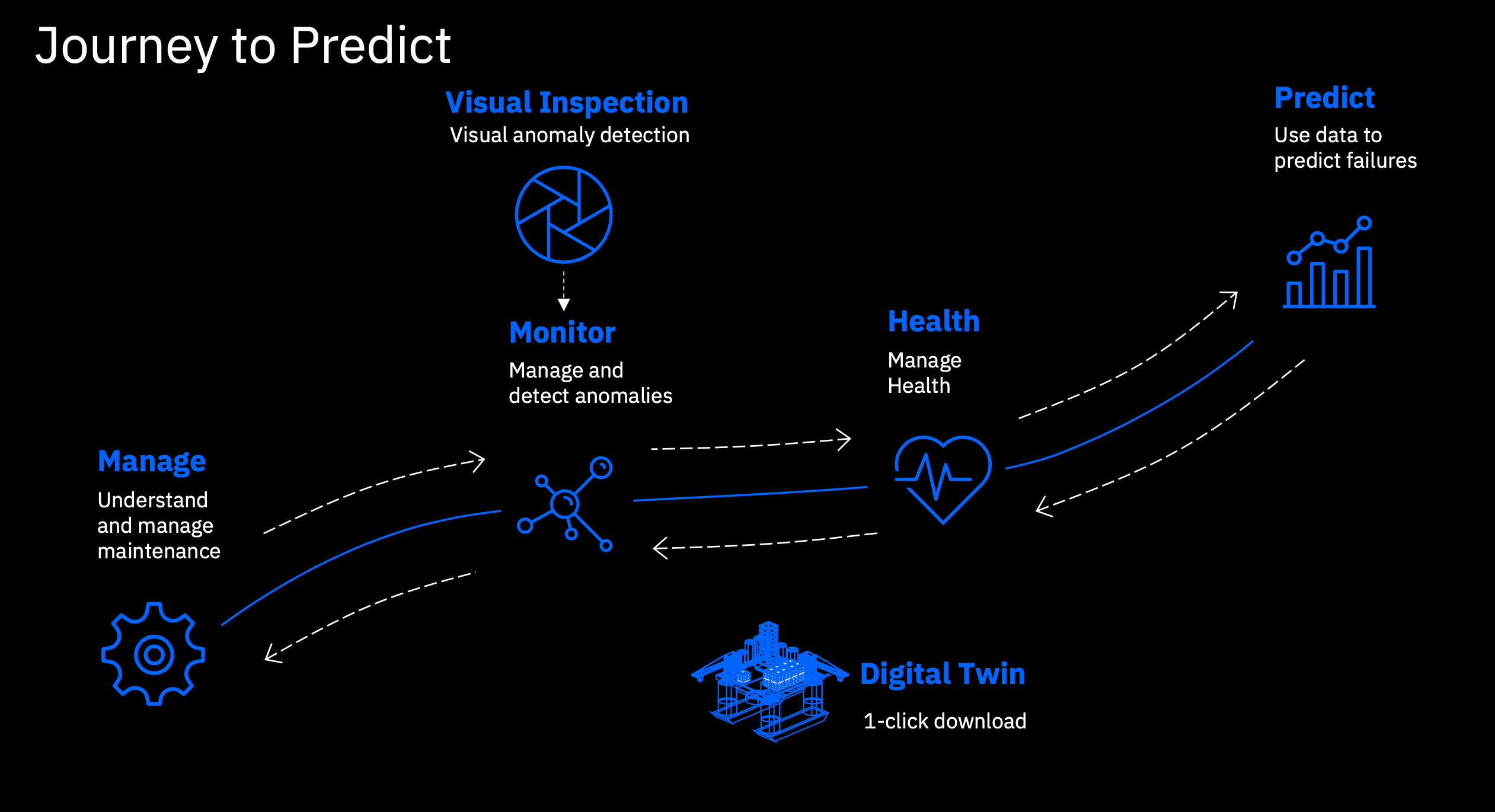

Intelligent asset management, monitoring, predictive maintenance and reliability in a single platform.

IBM Maximo Application Suite (MAS)

IBM Maximo is an end to end asset lifecycle management solution and the EAM market leader world wide, including the advanced features of MAS 8.0. It gives you a complete view of all of your company’s assets, preventive and corrective maintenance management processes, management purchases, contracts, work orders … making it the best asset management software.

Moreover, Maximo has been in the leader section of the Gartner Magic Quadrant continuously since 1998 and is widely used by organizations of all sizes and in all sectors around the world.

Transitioning to the versatility and power of IBM Maximo Asset Management, regardless of your business’s size or industry, it serves as a robust platform that seamlessly integrates asset management and maintenance functionalities. Whether you deal with processing equipment, laboratory assets, manufacturing facilities, offices, or warehouses, IBM Maximo Asset Management offers tailored solutions to meet your unique needs.

Benefits

Increase Efficiency

MAS will help you reduce costs and enhance the efficiency of asset maintenance within your company.

Streamline and unify operations

A single integrated platform provides a comprehensive view of assets across your organization.

Advanced Analytics

With robust data collection capabilities, the resulting analyses will enable you to assess your organization effectively.

Pay for only what you use

You have full entitlement to the suite with the flexibility to choose and control your license capacity.

Deploy on any cloud

With the successfully proven workflows available in Maximo, your team can execute cross-functional maintenance tasks on deadline.

Flexibility

MAS allows you to customize the system to meet your specific requirements.

Application Features

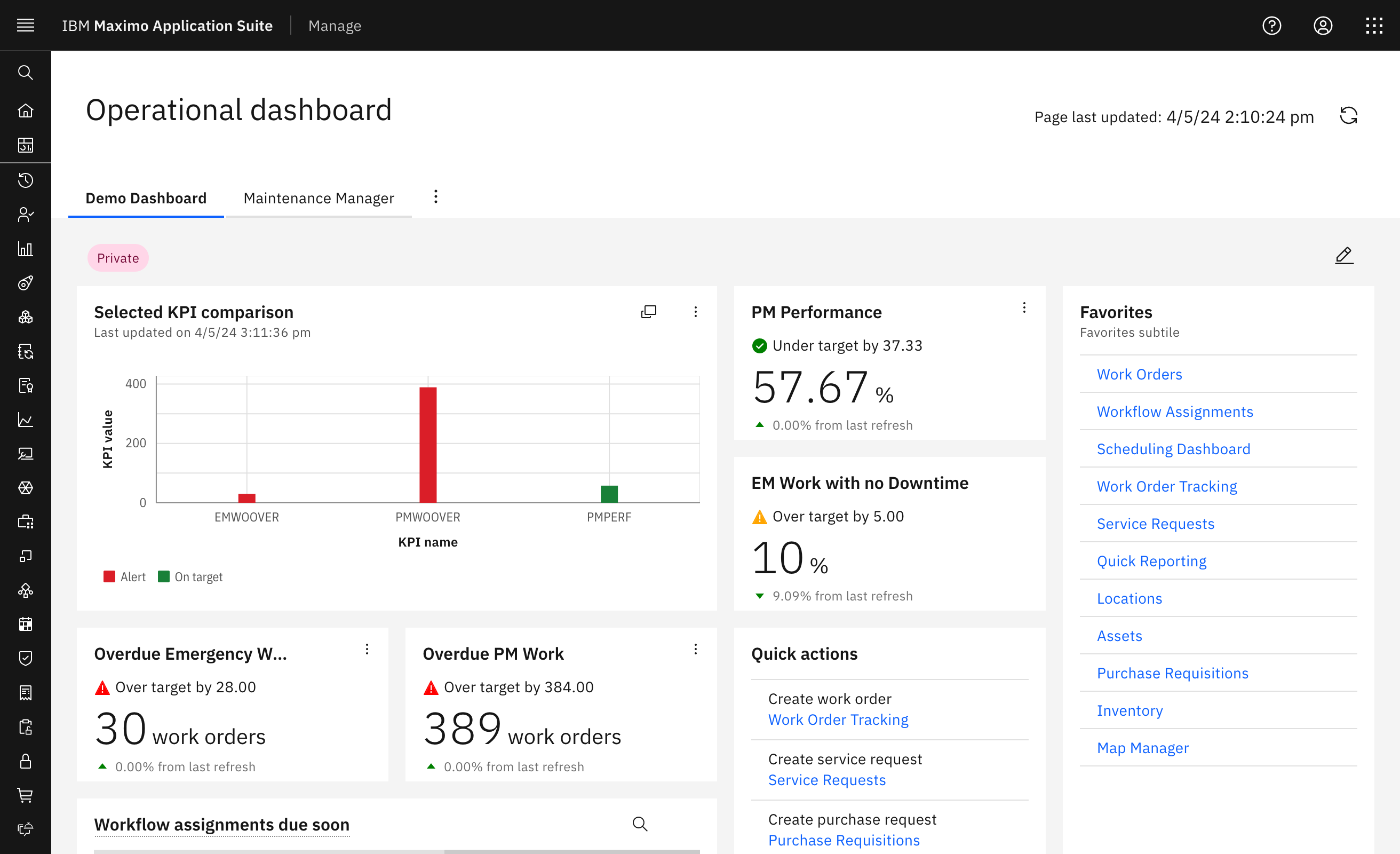

Maximo Manage (EAM)

Maximo Manage is the core asset management solution within the IBM Maximo Application Suite. It offers a comprehensive enterprise asset management (EAM) platform that helps organizations track and manage physical assets throughout their lifecycle. From procurement and inventory management to maintenance and decommissioning, Maximo Manage optimizes asset performance, reduces operational costs, and improves reliability by offering:

- Work order management: Streamline work processes for maintenance, repair, and operations.

- Asset lifecycle management: Gain visibility into the status, performance, and lifecycle of assets.

- Preventive and predictive maintenance: Schedule maintenance tasks to minimize downtime and extend asset life.

- Inventory and procurement management: Manage spare parts and procurement processes to ensure critical materials are available when needed.

- Regulatory compliance: Ensure adherence to safety, environmental, and other regulatory requirements

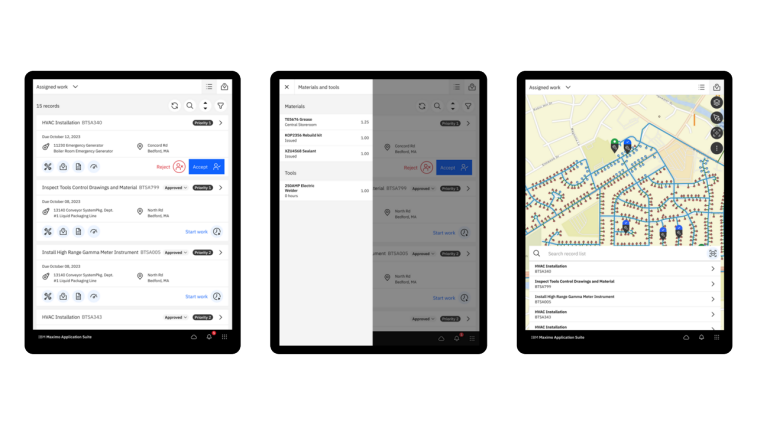

Maximo Mobile

Maximo Mobile empowers field workers with a mobile application that extends Maximo’s asset management capabilities to any location. This application is designed to work both online and offline, ensuring that field workers can continue to perform their tasks without connectivity interruptions. Maximo Mobile provides:

- Work execution: Field technicians can access work orders, capture data, and complete tasks directly from their mobile devices.

- Mobile inspections: Create and perform asset inspections, including capturing readings, taking photos, and recording notes.

- Offline capabilities: Synchronize data when internet connectivity is restored to keep workers productive in remote areas.

- Augmented reality (AR): Enhanced visual inspection and guidance for field staff using AR to view asset details and procedures.

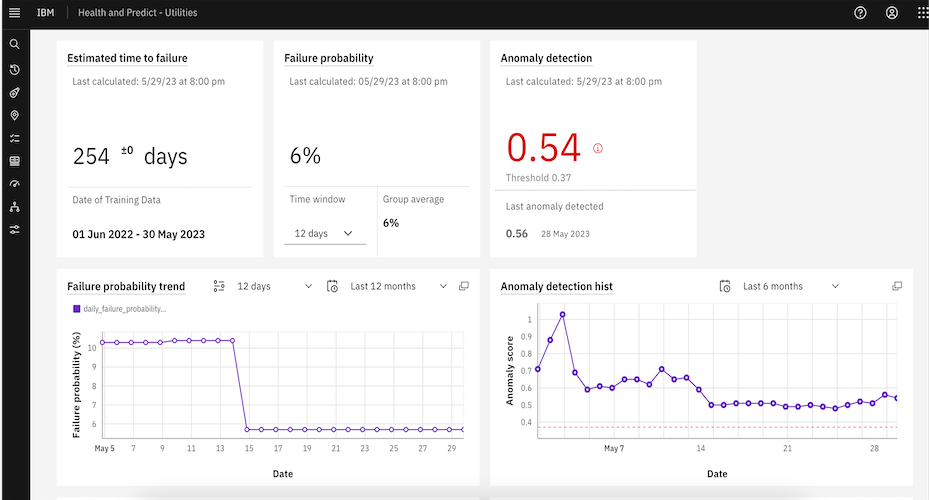

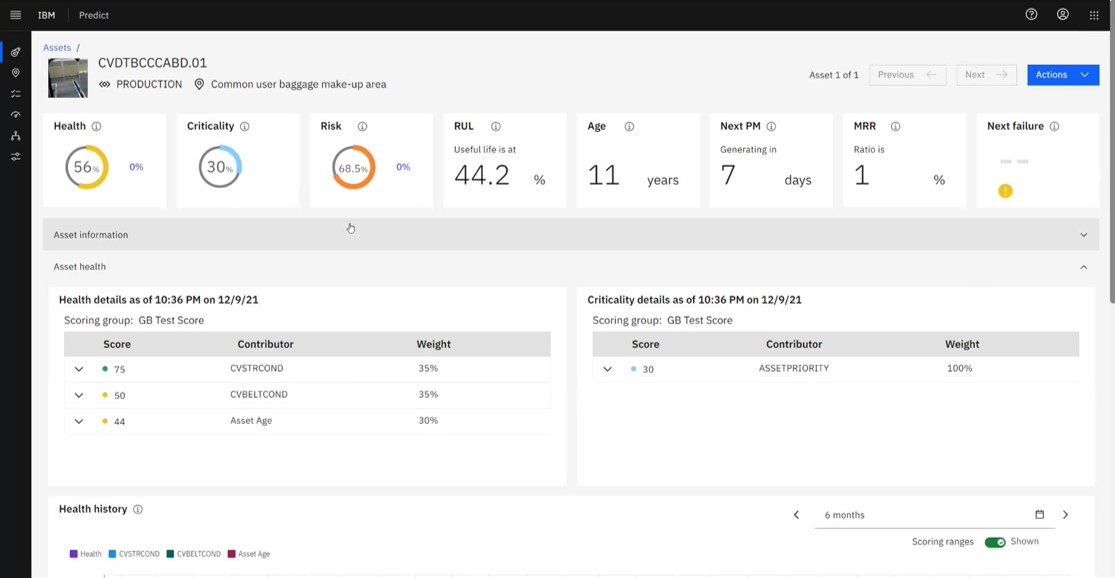

Maximo Health

Maximo Health provides a robust asset health monitoring solution that helps organizations assess and improve the condition of their critical assets. By integrating data from IoT sensors, maintenance records, and operating conditions, Maximo Health delivers:

- Real-time monitoring: Track asset performance and health in real-time using IoT sensor data.

- Anomaly detection: Automatically identify potential problems with assets through data analytics and machine learning.

- Health scoring: Assign health scores to assets based on a variety of factors, including age, usage, and maintenance history.

- Condition-based maintenance: Shift from reactive to proactive maintenance by acting on asset health insights.

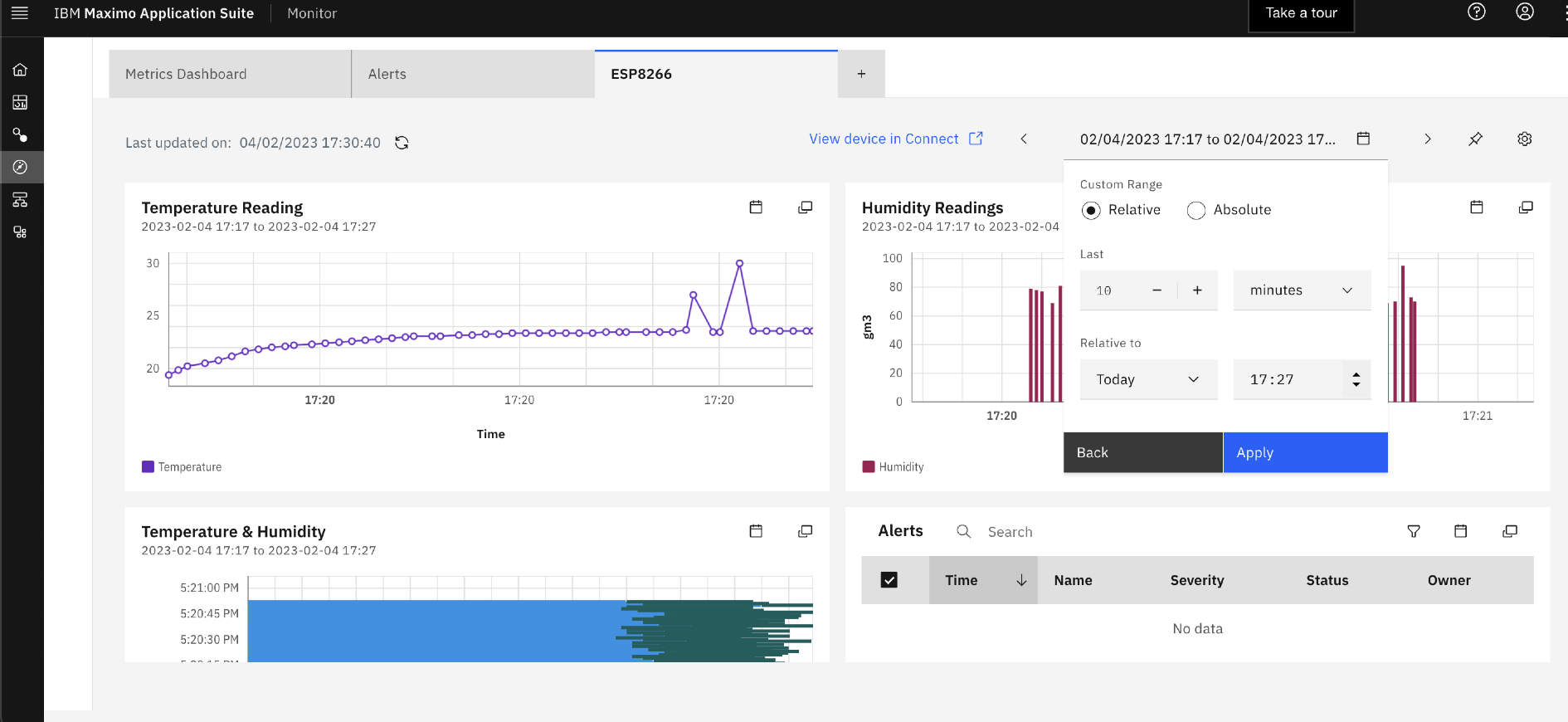

Maximo Monitor

Maximo Monitor offers advanced IoT monitoring capabilities for real-time tracking and alerting on asset performance. It integrates with IoT sensors to collect data on key performance metrics and provides dashboards and alerts to ensure rapid response to issues. Features include:

- Real-time IoT monitoring: Monitor critical asset parameters such as temperature, pressure, vibration, and more in real-time.

- Customizable alerts: Set thresholds and receive alerts for abnormal conditions or performance issues.

- Anomaly detection: Use machine learning to detect deviations from normal operating conditions.

- Root cause analysis: Diagnose asset failures and issues with detailed data and insights from IoT data streams.

Maximo Predict

Maximo Predict uses predictive analytics to forecast asset failures and maintenance needs. By leveraging historical data, IoT sensor readings, and machine learning algorithms, Maximo Predict helps organizations prevent asset failures before they occur. Its key features include:

- Failure prediction: Predict when assets are likely to fail, allowing for preemptive repairs.

- Risk assessment: Evaluate the risk of asset failure based on factors like operating conditions and historical data.

- Maintenance optimization: Optimize maintenance schedules by predicting the optimal time for interventions.

- AI-driven insights: Use artificial intelligence to analyze patterns in asset performance and predict future behaviors.

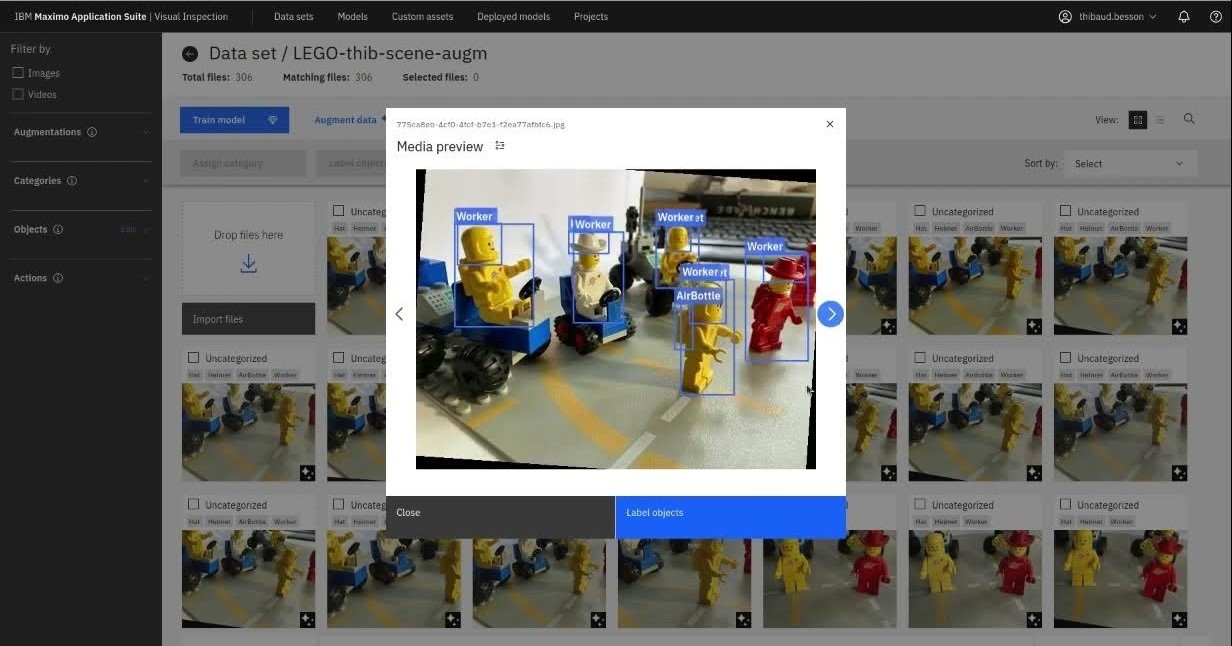

Maximo Visual Inspection

Maximo Visual Inspection leverages artificial intelligence to provide computer vision-based asset inspection. This tool allows organizations to analyze visual data, such as images and video, to detect defects, wear, or damage in assets. Key features include:

- AI-powered inspections: Automatically detect defects in equipment or assets using AI models trained on visual data.

- Defect identification: Identify potential issues like corrosion, cracks, or misalignments in real-time during visual inspections.

- Automated quality control: Streamline quality control processes by automating visual checks on production lines or in the field.

- Cloud or edge deployment: Deploy inspection models on cloud infrastructure or edge devices to support remote and disconnected environments.